Core Components and Technical Insights of Diesel Generator Sets

—— Presented by SHANLI Yuchai Technical Center

Diesel generator sets are widely used as independent power sources in construction, industry, telecommunications, healthcare, and other fields. Especially in areas with unstable or inaccessible grids, they serve as critical backup or prime power systems. This article provides a technical overview of the core components of diesel generator sets and introduces application scenarios and technical selection considerations based on SHANLI Yuchai’s R&D practices.

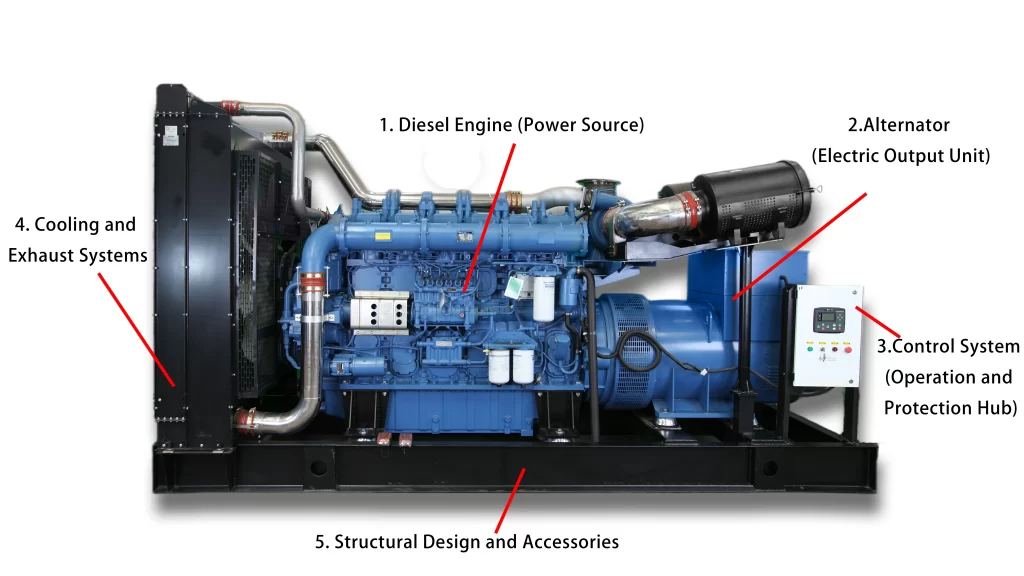

I. Main Structural Components of Diesel Generator Sets

1. Diesel Engine (Power Source)

The diesel engine is the power core of the generator set, converting the chemical energy of diesel fuel into mechanical rotational energy. Key performance parameters include:

- Rated power and torque curve, determining load capacity;

- Fuel consumption rate, directly impacting operating costs;

- Emission standards, affecting regulatory compliance and environmental performance;

- Cold start capability, particularly critical in cold or high-altitude environments.

Engine selection plays a decisive role in the overall performance of the generator set. Common brands in the industry include Yuchai, Cummins, Perkins, and Mitsubishi, depending on specific client needs regarding performance, budget, and maintenance accessibility.

2. Alternator (Electric Output Unit)

The alternator, driven by the engine, converts mechanical energy into AC electrical output. Key parameters include:

- Voltage regulation stability: Voltage adjustment rate is typically controlled within ±1%;

- Insulation class and temperature rise control: H-class insulation with a winding temperature rise generally ≤80K;

- Short-term overload capability: Usually up to 150% of rated power, handling transient load impacts.

Brushless designs and digital AVR excitation control systems are standard, ensuring stable output and operational reliability.

3. Control System (Operation and Protection Hub)

The control system manages engine start/stop, voltage/frequency adjustment, real-time monitoring, and protection functions. A mature control system should offer:

- Manual and automatic start modes;

- Real-time monitoring of voltage, frequency, oil pressure, coolant temperature, etc.;

- Fault alarms and safety shutdown protections;

- Support for ATS (Automatic Transfer Switch) with switching times typically within 8 seconds.

4. Cooling and Exhaust Systems

Significant heat generated during diesel engine operation must be dissipated via a radiator and fan cooling system to maintain optimal working conditions. The alternator section generally employs natural air cooling.

The exhaust system channels and muffles emissions through silencers and flexible joints. If required, devices like DPFs and DOCs can be installed to meet stricter emission regulations.

5. Structural Design and Accessories

Generator sets are usually mounted on steel bases, with structural forms such as open-type, soundproof, weatherproof, or mobile trailer-mounted designs. Auxiliary systems include:

- Fuel tanks (integrated or external);

- Vibration isolation systems;

- Grounding and protective designs;

- Anti-corrosion coatings (following ISO 12944 standards).

II. Technical Achievements in SHANLI Yuchai Product Design

As an officially authorized OEM partner of Yuchai Power, SHANLI Yuchai has been dedicated to the R&D and manufacturing of diesel generator sets for over 20 years. In key technical aspects, the company continuously optimizes in the following areas:

- Power System Adaptation

Primarily equipped with Yuchai engines, with optional Cummins, Perkins, and Mitsubishi engines available, covering a power range from 30kW to 2000kW. - Electric Output System

Independently developed SL series brushless alternators using digital AVR excitation technology, achieving voltage regulation accuracy within ±1%. - High-Altitude and Special Environment Adaptations

Special design modifications for high-altitude (up to 3000 meters), high-temperature, and high-humidity environments, ensuring reliable performance. - Emission and Environmental Upgrades

Mainstream models comply with China Non-road Stage II and Stage III emission standards, with some models upgraded to Stage IV for specific market needs. - Structural Optimization and Application Expansion

Flexible configurations including standard open-type, soundproof, weatherproof, and mobile types; soundproof models achieve noise levels between 68–72dB at 7 meters.

III. SHANLI Yuchai Product Series and Application Scenarios

| Series Name | Power Range | Application Scenarios | Key Features |

|---|---|---|---|

| Standard Construction Series | 30–800kW | Infrastructure, construction sites | Low purchase and maintenance costs, high reliability |

| Industrial Support Series | 100–2000kW | Factories, data centers, mining sites | Strong continuous load capacity, supports paralleling |

| Silent Series | 20–500kW | Hospitals, hotels, residential standby | Noise control designs for sensitive environments |

| High-Altitude Series | 50–1000kW | High-altitude regions (>2000 meters) | Enhanced cooling and fuel systems for thin air conditions |

| Special Customized Series | Custom range | Marine, oil fields, explosive environments | Marine CCS certification and explosion-proof options (Ex d IIB T4) |

IV. Export Capability and Service Supportrs?

SHANLI Yuchai diesel generator sets have been exported to Asia, Africa, South America, and other regions, covering industries such as construction, telecommunications, energy, and manufacturing.

Service and support highlights:

- Availability of 50Hz and 60Hz models, matching global power standards;

- Customizable configurations upon client request, such as external fuel tanks, ATS interface, special voltage/frequency outputs;

- Export units are accompanied by multilingual operation manuals and technical documentation;

- Comprehensive spare parts supply for after-sales service assurance.

V. Learn More

Visit SHANLI Yuchai’s official website www.gkgenset.com to explore more product details and project references, or contact our sales and technical support teams for customized power solutions.

Technical Statement

This document is compiled by SHANLI Yuchai Technical Center.

Part of the data is referenced from:

- Yuchai Power “White Paper on Non-road Diesel Engines”

- GB/T 2820.5-2009 “Reciprocating Internal Combustion Engine Driven Alternating Current Generating Sets – Part 5”