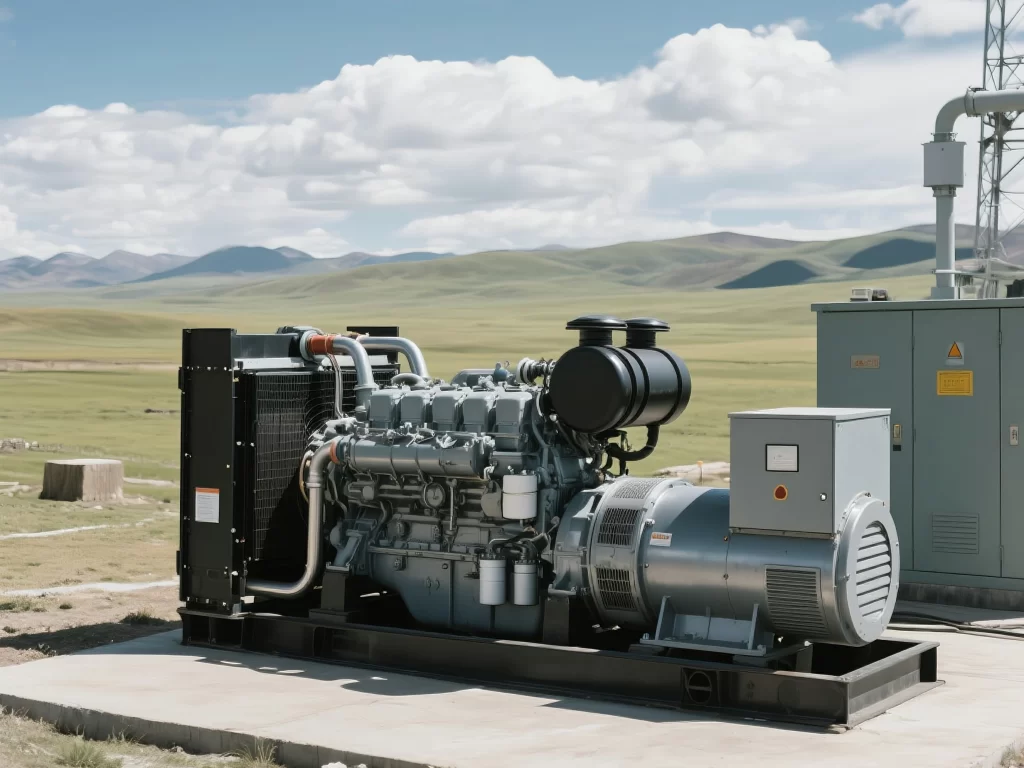

Impact of High-Altitude Environments on Diesel Generator Sets and Professional Solutions

Operating diesel generator sets in high-altitude regions presents significant technical challenges due to thin air, low oxygen levels, low ambient temperatures, and strong ultraviolet radiation. These environmental factors directly affect power output, combustion efficiency, electrical reliability, and overall service life.In this guide, we explore key technical adaptations for high altitude diesel generator solutions.

As an official OEM manufacturer for Yuchai, Shanli Power provides expert high-altitude solutions based on extensive field experience and in compliance with the industry standard T/CES 123-2022.

I. Environmental Impacts on Diesel Generator Sets in High Altitudes

| Aspect | Impact | Cause |

|---|---|---|

| Power Reduction | 10–12% power loss per 1000 m (naturally aspirated); 5–8% for turbocharged engines | Lower oxygen density reduces combustion efficiency |

| Increased Fuel Consumption | Up to 8–12% increase at 3000 m | Incomplete combustion due to low oxygen |

| Reduced Cooling Efficiency | Temperature rise of 0.5–1°C per 1000 m | Decreased air density weakens heat dissipation |

| Difficult Cold Starts | Battery capacity drops by 20–30%; prolonged start times | Low ambient temperatures, higher diesel viscosity |

| Electrical Failures | Arcing, insulation breakdown, accelerated aging | Lower dielectric strength; strong UV radiation |

| Increased Mechanical Wear | More carbon deposits, poor lubrication | Incomplete combustion; poor oil fluidity at low temp |

| Excessive Emissions | Higher CO, HC, and PM output | Incomplete combustion |

II. Technical Solutions for High-Altitude Operation

1. Engine Selection & Power Correction

- Use high-altitude turbocharged and intercooled engines.

- Reduce rated power by 5–8% per 1000 meters altitude increase.

- For elevations above 3000 m, reserve 15–20% power margin in system design.

2. Fuel System & Combustion Optimization

- Use -10# to -35# light diesel depending on climate.

- Employ electronic high-pressure common rail systems for precise fuel injection and optimized combustion.

3. Enhanced Cooling System

- Prioritize liquid-cooled systems with large-capacity radiators and auxiliary fans.

- Avoid air-cooled models in extreme altitudes or reinforce airflow design.

4. Cold Start Adaptation

- Equip with cylinder preheaters, glow plugs, and electric heating pads.

- Use fully synthetic engine oils (e.g., SAE 0W-40 or 5W-30) for better flow in low temperatures.

- Add ether start kits for extreme cold starts.

5. Electrical System Protection

- Increase clearance distances and insulation levels in generators.

- Use UV-resistant materials such as silicone rubber cables.

- Apply anti-dust, anti-moisture, and UV-resistant coatings.

- Integrate Automatic Voltage Regulators (AVR) for stable voltage output.

6. Emissions Control

- Install DPF (Diesel Particulate Filter) and SCR (Selective Catalytic Reduction) systems.

- Regularly clean injectors and combustion chambers to prevent carbon buildup.

7. Maintenance & Operation Guidelines

- Shorten service intervals—increase maintenance frequency by 30–50% for filters and oil.

- Avoid long-term low-load operation.

- Operate generators during warmer daytime hours when possible.

III. Shanli High-Altitude Generator Set Advantages

As the largest Yuchai OEM in Central and Southern China, Shanli Power delivers tailored generator sets for harsh high-altitude environments:

- Enhanced Power Output: Equipped with Yuchai turbocharged engines tested at elevations up to 5500 meters.

- Intelligent Control: Dual regulation system (AVR + ECU) ensures voltage stability within ±1%.

- Altitude Simulation Testing: Each set undergoes 72-hour high-altitude simulation testing before shipment.

- Scientific Sizing: We provide altitude-based power correction charts to ensure precise matching.

IV. Conclusion

To ensure reliable diesel power generation in high-altitude environments, generator sets must be professionally configured, carefully selected, and rigorously maintained. Shanli Power is committed to delivering robust, high-performance solutions that perform reliably under the harshest conditions.

📞 For more information and product updates, please contact us

Shanli Diesel Generator Sets | Your Trusted Power Partner

🌐 Visit Website | 📧 sales@gkgenset.com | 📱 Chat Now on WhatsApp